Quality Control Ensures Superior Vinyl Products

Quality is the First Benchmark

To ensure the highest quality in our manufacturing process, VEKA meticulously examines and verifies every ingredient used in our compound formulations. Each batch of mixture or compound is carefully sampled and tested to ensure proper blending. Stringent controls are in place to guarantee that every ingredient and compound meets VEKA's stringent in-house standards.

We leave no room for compromise when it comes to the quality of our raw materials. Once our compounds are heated and extruded, we conduct further quality tests to ensure the highest industry standards are met.

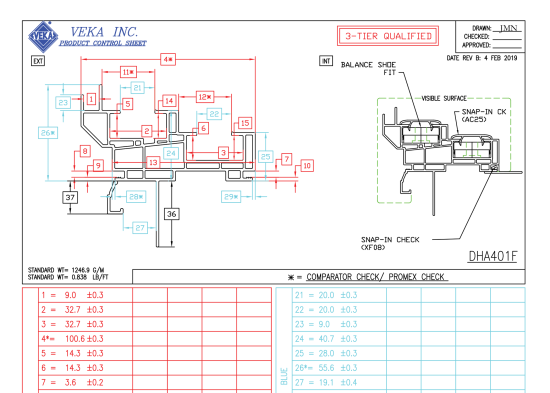

Using precise measuring equipment and visual comparators, we check the dimensions of our profiles against preset design tolerances. This detailed process guarantees that our products adhere to the strictest quality standards set by the Fenestration and Glazing Industry Alliance (FGIA).

VEKA Meets FGIA/AAMA Standards for Quality and Consistency

VEKA's Quality Control program is thorough and includes a team of inspectors who regularly walk the production floor to identify any visual defects. They perform these checks multiple times each day. The lab inspection process involves monitoring the weight, color, and shape of profiles to ensure they maintain their dimensional integrity and the profile meets specifications according to our three-tier blueprint program.

This three-tier system is consistently applied to all VEKA profiles, providing a precise understanding of customer tolerance requirements and balancing form versus function.

In compliance with FGIA (Fenestration and Glazing Industry Alliance) requirements, our lab team conducts checks on impact values, shrinkage based on heat testing, and heat resistance properties for all three-tier qualified profiles. All data is meticulously recorded using our tracking software. Our commitment to quality is aimed at ensuring and confirming the highest standard of quality in our products.

As an accredited supplier, we comply with the FGIA/American Architectural Manufacturers Association (AAMA) standards, which are established benchmarks for the fenestration industry. Many of our customers require FGIA compliance as part of their material and product requirements. The end result is a lineal that is easy to fabricate and consistent in shape, color, and overall integrity.